Die cut Boxes: Creation Process for Custom Boxes

The custom die cut boxes have a creative process that is more effective and rival to any other process that is geared towards the production of custom boxes. Custom boxes are the boxes that have the specifications that are provided by the customer or the client of a box manufacturing company that provides information on how the boxes are to be formed in terms of shape, looks, feel, size and outer printing for branding purposes.

Die cut boxes in contrast with the Regular Slotted Container (RSC) are highly customizable. These boxes give the freedom of production that no other known technology is capable of providing under any circumstances.

The Importance of the Custom Die Cut Boxes

This is an age of technological development in boxes that where the quality of boxes seems to overweigh the product inside the box. This can be denoted by the fact there are businesses around the world that are spending more currency on shaping and customization on the product boxes than on the product itself.

The main reason behind this anomaly is that it has been found through research on many different products and the product boxing that proves that the same product with better-looking boxes can boost the sales as much as 33%. Many soft drink companies like Coca-Cola has taken this gold rush to a step further and has provided evidence with the experimentation that suggests that their product users taste from their eyes. If the bottles of a drink are altered in a certain way without any taste change in the soft drink can lead to change in consumer behavior claiming the change in taste on a large scale.

All the changes that a company need in its bottling of a product come from the die cut process in which dies are used to cut layers of cardboard layers that are later folded into boxes at the time when the product is packaged inside. Before a box manufacturing company takes the order and prepares the boxes and packages and ships the flattened boxes to its clients as per order. The Die cut boxes also reduce waste of the material. The die cut boxes are also efficient on resources like machines required to cut the boxes and the tapes and the glue tha8t might be consumed during the production process.

The boxes that are prepared with die cut boxes have to be mocked up on computer graphics and there is some information input that the customer or the client of a box manufacturing company provides.

The following step by step process takes the information from the client of a packager to the manufacturing facility of the packager in a digital environment until a physical box is made which usually is a prototype in the first go and becomes a part of the mass production once it has been approved by the client.

Step#1: The Size and the File information

The first step of the digital journey of the boxing is the first step where the idea is conceived. What actually happens is that a person who is looking for a boxing solution approaches a box making company through any channel that can be from a reference from another customer, a telephone call or from a chatting interaction on the website of the box making company. The client provides the size and the dimensional information of the product that he or she requires.

This size of the product implies that the box size should be the bit larger to make the product fit inside the box. The computer software that is used to create a digital mockup with die line is Adobe Illustrator.

Adobe Illustrator is natively very good at creating a computer graphics image for the box that the client requires. The only limitation of this computer software is that this it is very good in 2D and the box graphic designer has to visualize the shape of the box in his or her head in the past. But, times have changed and the third party software plugins of Adobe Illustrator has been created by third-party software companies. These plugins can convert a 2D image into 3D which really boosts up the productivity for the designer and mitigates the chances of any mistakes or design flaws.

Step#2: Materials for boxes

As soon as the computer graphical the next step is that the material for the box or the boxes has to be arranged. This is shipped in from retail associates and it usually comes in stacks of large sheets of cardboard. These sheets are later fed into machines that are fitted with the die tool.

Step#3: Confirmation of Style and Size

The style and size are finalized in this step while examining the materials for boxes as soon as it arrives. The style is the crucial part in the effort to make the product look great and many companies provide a 3D graphics of the boxes to the client as he approves it or requests a prototype and the design process moves forward.

Step#4: Making of Die cut Template for boxes

The pen tool in the adobe illustrator is phenomenal when you design a die cut template for boxes for the make that will eventually become the box for the product that the client manufactures. It sometimes takes a few attempts to determine the position of the flaps and the size of the different other parts of the box that are designed. You can put arrows at the parts of the template or the computer mock-up to indicate the parts that are up determining the direction of the flow of the artwork.

Step#5: Determination of Cuts and Folds in a Template

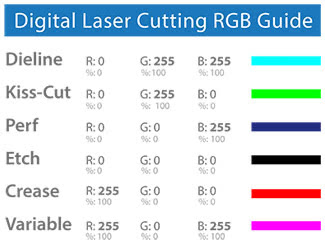

The computer-generated template has lines of two distinguishable colors to help the professionals and experts to determine the type of finishing that is required on the two different types on the smart press machines where the die line will take an actual physical shape.

For example, you can see a template of a soapbox that has been made with blue and red lines. The red lines are the places at which the cardboard will be cut and the red lines will determine the folds in the boxes that will roll out for the boxes.

There are other colors also that can be used to determine other actions that may be taken in the creation process of the boxes.

The parts of the box that will be folded which are called the crease should not over the printed area because they will remove ink.

Once you are done with the design side of the box, you can save them in a pdf file which is a mandatory step. Your template for the box is ready. This way die cut boxes provides a highly customizable solution that leads to the die cut boxes wholesale for the box producing company as soon as the order is approved by their customer.